Additional Contributors: Denise Allen, Valérie Carpentier, Annabelle Collinet, Pete Dandridge, Nicolau Escanilla Artigas, Susanne Gänsicke, Laurence Garenne-Marot, Arlen Heginbotham, Andrew Lacey, Elsa Lambert, Susan La Niece, Benoît Mille, Chandra L. Reedy, Annick Texier, Jeremy Warren

This chapter serves as a guide to assist in distinguishing the disparate features that indicate the process by which a was translated into a —the sequence of steps that led up to the of the bronze, or casting process. The chapter focuses on the two most common approaches: and . and casting other than sand casting will also be discussed. For a detailed description of the different processes, see GI§2. Within these broad categories there are a variety of alternative procedures whose traces are explained. These often leave characteristic features discernible via visual examination of the work’s external and/or internal surfaces.

However, many of the features that relate to the construction and structure of hollow bronzes, such as diagnostic variations in the thickness of the bronze, or evidence of the various metal inserts such as and , are only discoverable through radiography. In many cases, access to the inside of a bronze may be impeded either by the shape and nature of the or by the remains of material. The description of each process will, therefore, fall into three sections: evidence on the outer surface, evidence on the inner surface, and radiographic evidence. A synthesis of all physical evidence related to the different processes is presented in table 4 Open viewer.

The way in which the metal was designed to flow through the is called here the “casting disposition.” Though most traces of this step, such as , are removed during , some do survive, and the chapter provides guidance on how to identify them.

Please be warned that the following provides only an indication of which features related to specific casting processes might be encountered on a bronze. It does not offer firm evidence, and it is essential to consult experts in the field for advice where required. For more, please read the overall disclaimer for the Guidelines (GI§4).

1 Characteristic features associated with lost-wax casting and direct life-casting

This section covers disparate lost-wax casting processes as well as a few other methods that also use a model that is sacrificed in the course of creating the void in the refractory mold into which the metal will be .

1.1 General evidence of lost-wax casting

How is it possible to identify whether a bronze was made using lost-wax casting? Evidence may come from both the working characteristics of the wax itself (used for the model or ) and the particularities of the processes. Intricate shapes, the presence of complex undercuts, or naturalistic textures in a cast may point to the use of lost wax, although this is not always the case. The very nature of wax means that it can be softened or melted by heat and shaped in numerous ways, for example modeling, carving, or casting. Therefore, bronzes that were produced from models made with wax often preserve traces of such manipulation on both the exterior and interior.

Warnings:

-

A wax sculpture may not necessarily be translated into bronze using the lost-wax process.1

-

Intricate shapes and undercuts may also be encountered in sand casting.

-

The transference of natural textures (such as fur or scales) could equally have occurred as a result of life-casting.2 Conversely, not all lost-wax casts display such features.

1.1.1 Evidence on the outer surface

When softened, wax is easily manipulated into a variety of shapes without tools: rolled into balls or coils, pinched into pointed tips, flattened and smeared, or just poured. Such shapes and certain marks—like the parallel lines left by a fingerprint as it pushes wax across the surface—may be clearly captured in soft wax, and later translated into bronze (figs. 48, 49, 50).

Furthermore, any number of tools may be used to shape, incise, stamp, or texture a wax model (see I.6§1.1). In most cases it is hard to identify the material from which the modeling tool was made, but generally:

-

Wooden modeling tools are often used to work with softer waxes.

-

Metal tools such as , pointed modeling tools, tools, and files are more successfully used on hardened wax when crisper details are required (figs. 51, 52).

-

Either type of tool can be used to create signatures and marks. And ’ marks are traditionally stamped in the wax model before casting (see I.6§1.3).

1.1.2 Evidence on the inner surface (of hollow casts)

Several types of features are characteristic of lost-wax casting, and can be diagnostic of the exact process used (as will be discussed in more detail in I.1§1.3 and I.1§1.4 below; see GI§2.2 for a description of the different lost-wax processes):

-

Drip marks and brushstrokes may have been produced during the creation of the wax layer by an indirect lost-wax process such as slush molding (see I.1§1.2, I.1§1.3, and I.1§1.4 below).

-

A smooth internal surface often occurs with lost-wax casting and particularly slush molding (fig. 53, I.1§1.2, I.1§1.3, and I.1§1.4). Some sand-cast animalier sculptures have been confused with wax (see I.1.n.21).

-

Uneven, thickened lips of metal around the circumference of a limb, sometimes accompanied by a distinct difference in wall thickness at that juncture, are often the result of wax-to-wax joints. These were created by fusing separately formed wax parts at the abutting edges using a hot tool. They are usually invisible from the outer surface, since the wax model is generally refinished to unify the form and conceal such features. The joints may be observable on the inner surface (fig. 54, Case Study 4).

-

Soft-edged lips of metal around or core pin holes reproduce the displaced wax formed when the core pin is pushed into a hollow wax model (fig. 55).

-

Small spherical globules are often the result of air bubbles trapped on the surface of the model when an and core formed as a slurry are used, and are eventually filled by the liquefied metal during casting (figs. 56, 57). Similarly, organic materials from the core may be translated into the bronze (fig. 58). These are characteristic of lost-wax casting using clay-based core.

-

Sharp, uneven fins of metal—or the jagged remains of those that have been coarsely cut down—tend to be , which occurs when the liquefied metal enters cracks that have formed in the or core. These are more commonly found in lost-wax casts with clay- or plaster-based cores (figs. 59, 60) as they are more prone to due to moisture content. Flashes in sand casts are relatively rarer, and most often form along the of ill-fitting piece mold sections either in the core (fig. 61) or, in extreme cases where the mold maker is less experienced, on the outer surface (fig. 62).3

Risks of misidentification/misinterpretation

- Wax-to-wax joints may be confused with certain types of metal joints, as in both cases there is often an uneven thickening of metal along the joint line (see I.5).

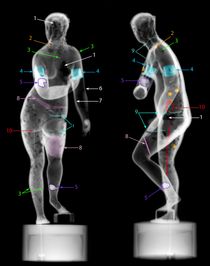

1.1.3 Radiographic evidence

Radiography may be the only way of detecting the aforementioned features if the internal walls of the bronze are not visible. This is particularly the case for the small spherical globules testifying to the use of a plaster core or ceramic shell. And because of their location on the interior, wax-to-wax joints are generally hard to see and often detectable only by these means. They usually generate a thickening and/or thinning of the metal around the circumference of a body part that has been attached, for example below the shoulders, at the top of the thighs, or at the neck. They may appear on the radiograph as:

-

a discontinuity in the metal wall thickness (fig. 63);

-

different densities due to the resulting difference in thickness of the parts that are joined (fig. 63);

-

a more or less straight line (fig. 64), or a circular or elliptical line (fig. 31).

Risks of misidentification/misinterpretation

-

Wax-to-wax joints may be confused with the juncture between two separately formed cores (fig. 65 point 8). The core may be built or filled in several steps, thus possibly generating joints visible on radiographs.

-

The absence of most or all of these features does not preclude the possibility of a bronze sculpture being a lost-wax cast or a life-cast.

1.2 Evidence of direct versus indirect lost-wax casting

There is a broad distinction between a direct cast, in which the original (wax) model is destroyed in the process of being translated into bronze (that is, the wax is burned out), and an indirect cast, in which a wax of the original model—a casting model or inter-model—is created for the purpose of casting (see GI§2.2). That said, it is not uncommon to find combinations of both.

1.2.1 Evidence on the outer surface

In direct casting, the overall shape is modeled from the outer surface (fig. 13) (in the direct wax-slab process, the model may also be worked from inside). This may leave specific marks, particularly when the modeling is done without tools. Among the characteristic features that point to modeling in wax that has been done freehand (without tools), the most easily recognized are:

-

rolled threads and rods of different sizes, which are an almost universal visual design form (figs. 12, 20, 66, 67, 68, 69),

-

amorphous blobs of softened wax squished or pinched between two fingers (figs. 70, 71).

But note that these are not definitive evidence of direct lost wax; see risks of misinterpretation enumerated below.

Conversely, in the indirect lost-wax casting process, the wax model that is intended to be cast is made from a mold. As a consequence, a firm identification of any feature relating to the mold used to create wax replicas allows us to reject the possibility that it is a direct cast. This includes seam lines:

-

raised ridges, which may correspond to traces of the piece mold possibly used to create a wax inter-model as part of the indirect process (figs. 72, 73, 74);

-

raised ridges, which may correspond to traces of the piece mold possibly used to create a plaster model that was then used in an indirect process (fig. 75).

Risks of misidentification/misinterpretation

-

The fact that the original model is fashioned in wax, and thus that the resulting bronze bears all aforementioned features, does not necessarily imply a direct lost-wax casting—or lost-wax casting at all. The waxy features may relate to an earlier model one or more steps removed from the actual casting model. This would be the case, for instance, when a wax model is replicated in plaster, perhaps amended with more wax, and then cast into a bronze , which is in turn used to create a sand cast.4

-

Wax models may be created by a combination of both indirect and direct processes. The outer surface of the wax inter-model, for instance, may be reworked during finishing by adding or altering details (fig. 68). In cases where there are multiple casts of the same model, this often accounts for variations in the different casts (fig. 76).5

-

If the original model is made of clay, similar evidence of modeling may be found on the final bronze as on a lost-wax cast. Both clay and modeling wax are soft materials that may be handled in a similar way, and thus an indirect lost-wax cast may be misidentified as directly cast. Sand casting may also be used to translate a clay model into bronze.

-

Seam lines from the piece mold used to make the wax may easily be confused with those produced by other processes using piece molds (for example, sand casting and piece mold casting, see I.1§2 below).

-

The remnants of flashing or feathering can look very similar to seam or mold lines once filed down (compare fig. 72 and fig. 77).

Open viewer

Figure 13

Open viewer

Figure 13

Open viewer

Figure 12

Open viewer

Figure 12

Open viewer

Figure 20

Open viewer

Figure 20

Open viewer

Figure 66

Open viewer

Figure 66

Open viewer

Figure 67

Open viewer

Figure 67

Open viewer

Figure 68

Open viewer

Figure 68

Open viewer

Figure 69

Open viewer

Figure 69

Open viewer

Figure 70

Open viewer

Figure 70

Open viewer

Figure 71

Open viewer

Figure 71

Open viewer

Figure 72

Open viewer

Figure 72

Open viewer

Figure 73

Open viewer

Figure 73

Open viewer

Figure 74

Open viewer

Figure 74

Open viewer

Figure 75

Open viewer

Figure 75

Open viewer

Figure 76

Open viewer

Figure 76

Open viewer

Figure 77

Open viewer

Figure 77

1.2.2 Evidence on the inner surface (or verso of a

relief)

It is not always possible to identify evidence that is characteristic of direct casting on the inner surface of hollow casts. The internal contours of direct casts can vary widely, and can be smooth (see Case Study 2; the direct slab process also yields very smooth internal contours) or roughly shaped. As the wax layer is formed over the core it will capture its shape and textures, including for instance:

An exception is the direct wax-slab process, or possibly the use of a “false core” (where the sculptor models over a core that is subsequently removed and replaced with another for casting).6

Risks of misidentification/misinterpretation

Reinforcing wires to bind the core have been observed for the lasagna technique, which is considered an “indirect” casting process (see I.1§1.4 below)

1.2.3 Radiographic evidence

The greater or lesser evenness in wall thickness of a bronze reflects the level of conformity between the shape of the core and the final shape of the sculpture. Some sculptors (assuming that they work on their own) will produce a core with a high level of detail and use some form of markers, such as , to help them control the overall thickness of the wax layer. Using preformed wax slabs of the same thickness will also ensure a relatively even layer of wax (fig. 28). But complicated features such as hair or smaller decorative elements, or any changes in the design that were not foreseen in the core, may result in thicker or thinner areas in the wax layer (and consequently in the bronze). Such larger discrepancies are often associated with a direct technique, especially with one-off casts (as opposed to multiples).

An armature reflecting the overall shape of the sculpture is more likely to be found in a direct cast, especially larger ones (figs. 13, 79), as it constitutes the structural “skeleton” of the sculpture over which the model is designed. But armatures might also be found in an indirect cast, inserted into the hollow wax inter-model before it is filled with core material.

A synthesis of all physical evidence related to the direct lost-wax process is presented in table 4 Open viewer.

Risks of misidentification/misinterpretation

1.3 Characteristic features of slush molding, wax

painting, and indirect wax-slab processes

These types of indirect lost-wax processes share the creation of a core after the wax model is made (figs. 16, 18, see GI§2.3 for a detailed description).

1.3.1 Evidence on the outer surface

The reusable mold used to form the wax inter-model may leave distinctive traces on the outer surface of the bronze. Gelatin molds, rubber molds, and plaster piece molds may all produce seam lines on the wax. Usually these features are removed during the refinishing of the wax inter-model, but not always fully. These may, however, not be considered singular to these processes (see I.1§1.2 above). See also I.1§1.1 above for the evidence common to all lost-wax processes. Securely identified examples of the indirect wax-slab process are rare. The way in which the metal curves in on the back of a relief could be the result of the bending of existing wax slabs around the core (figs. 81, 82).

1.3.2 Evidence on the internal surface

The following features can point to any of the three processes:

-

traces of working of the wax such as tool marks (figs. 83, 84), like those left by the hot spatulas that were used to melt together separate wax sections at the joints;

-

evidence of localized masses of soft wax pressed into areas that needed thickening, and related fingerprints (fig. 50);

-

evidence of core pins, whether inserted from inside7 or outside, or by waxy lips, molten drips, and/or metal excrescences when core pins were pushed into the hollow wax before the core was filled in (fig. 85);

-

internal sprues (fig. 86).

The following features are characteristic of slush molding:

-

a smooth, flowing surface on the interior of the cast that is conformal with the outer contour (that is, the inner surface echoes that of the outer), while rounding out any sharp transitions (figs. 53, 87);

-

tide lines and/or drips left by the wax as it was slushed around and poured out of the mold (fig. 88).

Brushstrokes are usually evidence of the molten wax being painted into the mold (figs. 21, 22, 55, 89).

Risks of misidentification/misinterpretation

-

Drips may stem from heated pins (see above), from wax slabs being cut by a hot tool (fig. 60), or (rarely) from thickening the edges of a hollow direct cast if it is possible to gain access to the interior, such as with the use of a false core (see I.1§1.2 above).

-

It is also possible for brush marks to be formed on the core and subsequently picked up by the wax.

-

Conformal casts may also be found in direct processes.

1.3.3 Radiographic evidence

The thinness of the wall and the close correspondence of the inner and outer contours are the most characteristic features of expert slush molding and of indirect wax slabs. Radiography is the ideal tool to reveal this. It can even help distinguish between the two processes because:

-

Slush molding leads to the rounding out of transitions (fig. 80).

-

Wax slabs of even thickness may ensure the most even thicknesses on a bronze (figs. 90, 91).

-

The overlap of wax slabs, typical of the indirect wax-slab process, might be revealed by radiography as a greater density due to thickening in the overlapping area (fig. 92).

-

Tide lines and drips produced during slush molding may be revealed as well (fig. 88)

Risks of misidentification/misinterpretation

-

Even and thin metal walls may be achieved by the direct wax-slab process.

-

Drips may stem from heated pins, from wax slabs being cut by a hot tool (fig. 60), or (rarely) from thickening the edges of a hollow direct cast if it is possible to gain access to the interior, such as with the use of a false core (see I.1§1.2 above).

-

Rounding out of transitions in the core is also found in direct lost-wax casts and bronzes formed with the lasagna technique.

Table 4 synthesizes all features that might be identified on a bronze related to these processes.

1.4 Characteristic features of the cut-back core and

lasagna processes

Unlike with slush molding and the use of indirect wax slabs, the core in both of these processes is produced before the wax model. In fact, the core serves to define the inner boundaries of the molten wax that is poured into the reusable outer mold, where it will fill the space created either by paring down the core or by the removal of the lasagna (figs. 23, 25).

Please be advised that these guidelines do not provide an exhaustive list or description of the variety of indirect processes and combination of processes that may have been used, but rather offer a firm basis of more common, documented examples. Table 4 synthesizes all features that might be identified on a bronze related to these processes.

1.4.1 Evidence on the external surface

There is no specific evidence. See I.1§1.1 above for the evidence common to all lost-wax processes.

1.4.2 Evidence on the internal surface

The following evidence is common to both processes: the internal surface of the wax model will capture the shape and tool marks, or fingerprints left on the core.

The following evidence is specific to the cut-back-core process:

-

The pared-down core often displays more angular transitions around the contours of the shapes (fig. 93).

-

Any tool marks left from the paring-down process may be captured in the metal surface (fig. 94, see I.6§1.1.3).

The following evidence is specific to the lasagna process: the core is not pared down, but built up to fit the mold, thus possibly generating different features:

-

The transitions around the contours of the shapes are very simplified, if not absent, instead of being angular (figs. 24, 95).

-

Specific marks due to the working of the lasagna from inside may be captured, such as the joints of clay sheets (figs. 24, 95).

Risks of misidentification/misinterpretation

-

The method of producing a cut-back core closely resembles that used in sand casting and can therefore lead to possible confusion between the two.

-

The less-defined contours of the lasagna layer resemble those generated by slush molding or possibly of direct lost-wax casting (see Case Study 5).

-

If wires were used to bind the core they may have become embedded in the inner surface of the bronze (fig. 96). Such wires are evidence that the core was formed directly, before the wax, and reinforced in this way. Although our sole known written mention of the procedure is in Benvenuto Cellini’s (Italian, 1500–1571) description of the lasagna technique (see Case Study 5), this procedure is not necessarily exclusive to the lasagna process.

1.4.3 Radiographic evidence

Both the lasagna and cut-back-core processes share some common radiographic features:

-

Inner and outer surfaces of the bronze are not always very conformal (that is, they do not closely follow the contours of the exterior), and the thickness of the walls, especially in areas of fine raised detail, tends to be uneven (figs. 80, 97).

-

Wires or tethers wrapped around the core for reinforcement before the wax is added and subsequently embedded in the inner surface of the metal will produce patterns of a slightly different density in a radiograph (fig. 34).

The differences between the two processes as evident through observation of the inner surface (see I.1§1.4.2 above) may also be seen on radiographs.

Risks of misidentification/misinterpretation

-

Non-conformality of the interior and exterior surfaces, and thick and uneven metal walls, are similar to those associated with direct casting (see Case Study 5).

-

An even thickening of the metal along a straight section may be evidence both of overlapping wax slabs and of a wax-to-wax joint.

-

As stated above (I.1§1.4.2), wrapping the core with wires is not necessarily exclusive to either the lasagna or the cut-back-core processes.

1.5 Characteristic features of the life-casting process

This process shares common features with lost-wax casting, as it entails the use of organic materials (for instance animal and vegetable forms or textiles) that can be fully or partially burned out of the mold (fig. 11, see GI§2.5.1).

1.5.1 Evidence on the external surface

On the external surface, this process:

-

produces a 1:1 scale of replication (although note the potential for shrinkage);

-

reproduces the texture of the original in every detail—something that would be a challenge through the use of modeling (figs. 27, 98, 99, 100);8

-

may result in seam lines. Natural objects that do not burn out so readily like crab or crayfish are often piece molded directly in the refractory material, which allows removal of the hard, carbonized remains. Therefore, seam lines may appear on the bronze (fig. 27).9

Risks of misidentification/misinterpretation

Animals and plant forms can also be reproduced in bronze by an indirect process, which can look very similar to these life-casts. In this case, reusable molds are taken from such models in order to produce wax inter-models that are often hollow and can be altered further at the wax stage.10 It can be difficult to distinguish between realistic casts that were molded directly versus indirectly on an animal or plant. For example, both may have seam lines.11

1.5.2 Radiographic evidence

A hollow cast may reveal drip marks or the use of core pins, both of which will suggest that a wax inter-model was used and therefore point to a cast from life.

Risks of misidentification/misinterpretation

A direct life-cast can be hollow, albeit rarely (see GI§2.5.1).

2 Characteristic features associated with sand casting and piece mold casting

Both of these processes consist of making the refractory mold in discrete pieces and removing the model.

2.1 Characteristic features of sand casting

In sand casting, a special sand is pressed onto the pattern within a sturdy frame structure to create removable sections (fig. 9, see GI§2.4.1). Simple shapes (for example medals and small, low reliefs such as Renaissance plaquettes) may only require a two-piece mold. Complex models will necessitate more complex molds.

2.1.1 Evidence on the outer surface

-

Relative lack of undercuts may point to a simplification of the model (or filling of the undercuts in the model) to create a piece mold.

-

A distinctive, even, granular roughness on unfinished areas on the surface (for example in hard-to-reach places) may represent the texture of a coarse, sand-molded surface before (fig. 101). Most first layers of sand on the outer layer are quite fine; such textures are more common for the core.

-

The location of divisions between the separately cast parts (the casting plan) will be different on a sand cast than on bronzes cast using other processes—something that only a founder can really explain (figs. 102, 103).

-

A thin, continuous, raised linear feature may correspond to a mold seam line formed at the joint lines of piece molded sections (see Case Study 3).

-

An offset, stepped, linear feature that either follows an obvious piece mold joint line, or disrupts or cuts across the modeling of an area of a cast, could be evidence of a misaligned piece mold.

Risks of misidentification/misinterpretation

-

None of the above features are specific to sand casting. In particular, complex undercuts can be achieved in sand casting (figs. 102, 103), and simplification of undercuts may also appear in indirectly cast bronzes.

-

Surface roughness may be due instead to fine pitting caused by , to acid cleaning, or to sandblasting typically used to remove investment in the ceramic shell process.

-

roughness due to sand molds and clay molds (for example, the lost-wax process, figs. 104, 105) may be hard to distinguish.

-

A relative lack of undercuts may reflect the artist’s composition rather than the process.

-

As mentioned above for indirect lost-wax casting, the remnants of flashing or feathering can look very similar to seam lines once filed down (see I.1§1.2 above).

-

Seam lines could equally testify to the use of piece mold casting (see I.1§2.2 below). More generally, the possible variety of molds used during the whole making process—mold used for creating the original model, wax mold, refractory mold—may generate a variety of seam lines that are easily confused.

-

Identifying whether or not the casting plan used for a specific bronze is indicative of the sand-casting process requires specialized skills, typically those of a founder.12

2.1.2 Evidence on the inner surface

The only feature that may be specific to sand casting is the grainy texture on the inner surface of a hollow cast or back side of a relief (figs. 101, 106, 107). The following features could also be observed inside or at the back of a sand cast, but are not specific to sand casting:

-

evidence of particular ways of planning the assemblage, often only visible from the inside if the finishing work used to conceal such joints was artfully done (fig. 108);

-

raised inscriptions produced by carving or impressing into the core (fig. 109);

-

geometric and/or cut-back shapes of the inner surface resulting from the characteristic paring down of the core (figs. 53, 107);

-

less core flashing compared to lost-wax casting (see I.1§1.1 above);

-

seam lines or flashing corresponding to joints between separate core sections (figs. 43, 61).

Risks of misidentification/misinterpretation

-

The evidence of the core having been pared down may also pertain to the cut-back core technique.

-

The limited amount of core flashing is not necessarily indicative of the process.

-

Although sand casting is the most common reason for a coarse, grainy texture, a coarse clay or plaster-based core can produce a similar appearance in the bronze.

2.1.3 Radiographic evidence

Much of the aforementioned evidence will be visible on radiographs (for example metal joints, shape of core, core flashing).

2.2 Piece mold casting

Here, the mold is formed over the model in separate sections made directly of refractory investment material (for instance kaolin or loam). The piece molds thus obtained may then be further reworked from the inside to create or enhance the decoration, before being reassembled over the pared-down core (fig. 26, Case Study 3).

2.2.1 Evidence on the outer surface

2.2.2 Evidence on the inner surface

This may include:

-

marks indicating that the core has been shaved down (fig. 118);

-

raised inscriptions on the inside that represent carving or impressing into the core.

2.2.3 Radiographic evidence

This may include:

-

walls of uneven thickness due to a more cursory shaving down of the core;

seam lines;

-

signs of chaplets or (also known as core extensions).

Risks of misidentification/misinterpretation

All of the aforementioned evidence may be encountered in other processes. The combination of a large number of these clues, however, may be indicative of this technique.

3 Characterization of features related to the armatures and core supports

Armatures, core pins, chaplets, and other core supports are generally made of metal, and this section aims to provide guidance for identifying their characteristics. Their functions are fully described in GI§2.6, together with the reasons for investigating them. The features that provide a focus for documenting these various features are their shape, size, and placement, as well as the material from which they are made.13

3.1 Armatures

-

Armature rods may project from the base or bottom of the sculpture and can be used to mount the work.

-

The exposed end of an iron armature rod that has been cut down flush to the surface may remain visible in the bronze surface and can be recognized by the buildup of rust, unless covered with (fig. 119) or hidden by an opaque .

-

Historically, many armatures were made of iron rods, in which case it may be possible to locate them using a magnet.

-

The recurrence of rods with similar dimensions and profiles among related sculptures may signal possible patterns in production.

Risks of misidentification/misinterpretation

-

The absence of an armature does not mean that there was none; armatures were often removed or cut off flush with the surface. Also, some armatures may have been made of organic materials such as wood and burned out or removed sometime after the sculpture was cast into metal (either before assembling separately cast parts, during fettling, or at some later stage). See GI§2.6.

-

Several radiographic views may be necessary to determine the shape and location of an armature, but may not be sufficient to discern other characteristics such as the profile of the rods or wires or the exact materials from which they were made (fig. 34).

-

Radiography may not always fully reveal armatures, since iron (and in rare cases wood) is less X-ray opaque than copper. Rusted iron is even less visible, and when rusted into laminated form may look like a sheaf of thinner rods. Access to the internal surface would allow for a visual assessment of such components.

-

Although there is a tendency to look for patterns and consistency in the materials used within a workshop, there are likely to be variations. Explaining these remains a matter of speculation. For instance, it is plausible that a founder made use of whatever rods and wires were available in the workshop.14 Also, the complexity of the armature is inevitably linked to the form of the sculpture (compare for example fig. 31 and fig. 34).

-

Relatively high amounts of iron in a copper alloy may be the cause of magnetic attraction as well, and so may confound identification of the presence of an iron armature using a magnet.15

3.2 Core supports (metal and other)

Below are clues that help characterize the categories of metal features that support the core, the so-called core supports (core pins, chaplets), as well as mold extensions, all of which are defined in the general introduction and Vocabulary. Armatures may also serve as core supports.

Evidence of core pins includes:

-

magnetic attraction, which if ferrous and not fully rusted will suggest the presence of an iron core support or core pin on the interior;

-

ends of extant wires, rods, or nails visible on the inside—a nail head on the inside means there was access to the interior to insert the nail, something occasionally found on larger sculptures (fig. 36);

-

linear features in radiographs that stand out from the forms of the cast bronze (figs. 37, 120);

-

paired holes in a radiograph, which might indicate the use of transverse core pins that pierce through the model from one side to the other (fig. 64);

-

round or square holes that pierce through the external surface and that have been left unpatched (or may be filled with organic filler such as wax or resin) (fig. 121);

-

a logical pattern of or patches of similar shape and size distributed over the entire bronze that would cover core pin holes (figs. 35, 64, see I.4§2.2);

-

wire acting as an internal core support that may be embedded in the core, and is usually only detectable by radiography (fig. 32).16

Chaplets, or “spacers,” are larger than core pins and are often made of the same copper alloy as the cast (figs. 38, 39, 122). They do not always bond with the cast metal and for that reason the outlines may be visible. Access to the internal surface or radiography is often key to identifying them.17

Mold and core extensions usually leave large regular openings in the metal wall, and are often repaired (figs. 28, 123).

Risks of misidentification/misinterpretation

-

It may not be easy to distinguish patched or plugged core-pin holes from other repairs (see I.4§2.2).

-

Core pins and chaplets are often well hidden by chasing and .

-

Core pins, chaplets, and internal core supports may be difficult to distinguish from armatures when they break through the surface of a bronze, as they are often made of materials of similar density, and so can be confused in radiographs.

-

Magnetic attraction may be due to an iron-rich copper alloy rather than indicating the presence of an iron armature (see I.1§3.1 above).

4 Sprueing and casting orientation

4.1 Sprueing system

It is virtually impossible to determine how the metal was fed through the mold (for instance in the case of a lost-wax cast), despite close study of a finished cast. In most finished bronzes, sprues tend to be cut off and the surface chased, making reconstruction of the sprueing disposition very difficult. On rare occasions the entire network, including the casting cup, is preserved. This can range from designing the sculpture itself in such a way as to take into account the distribution of the metal (fig. 71) to preserving the full network of sprues for demonstration purposes (fig. 46). In most cases only occasional traces survive. These can take various forms:

-

The occasional sprue may be preserved in its entirety, either on the outside of the bronze (fig. 124) or incorporated as an integral feature of the sculpture. They may also survive intact on the inside of a bronze (fig. 86).

-

More often, remnants of sprues survive only as small protuberances when they were cut off and only crudely leveled with the surrounding surface. Such remnants are found more readily along the bottom edges or inner or rear surfaces where removal was not as carefully executed.

-

More rarely, shrinkage, , or differentiated corrosion due to microstructure differences may mark where the sprues or gates were located. Cooling in those areas is slower because there is a greater volume of metal, thus impacting the microstructure (see I.2§3).

-

Core vents, also known as lanterns (figs. 6, 43), may be visible by radiography (see GI§2.6.3, Case Study 6).

Risks of misidentification/misinterpretation

-

Some sculptural features and/or decorative elements may be confused with remnants of a sprue.

-

Differential corrosion may stem from a variety of reasons other than the aforementioned microstructural differences in sprue areas (fig. 125).

4.2 Evidence of the orientation of a cast

It is a challenge to determine whether a sculpture was cast upside down, vertically, or horizontally, and also whether the metal was poured directly into the sculpture or fed in in a more controlled fashion by directing the metal to the bottom of the mold first (that is, via an “indirect feed”).

The following features may help to determine some of this, and are all considered :

-

Porosity tends to form in the regions of the cast that are higher during casting, since bubbles rise. Any concentration of porosity may, therefore, be a good indication of the direction of the casting disposition, as mainly seen using visual and/or radiographic examination (figs. 126, 127).

-

Similarly, wash from the refractory mold—mainly from sand molds—will rise to the surface of the cope. The resulting floating debris would cause easily recognized casting defects.18

-

Potential discrepancies in the lead content in the case of leaded alloys should see the heavier lead sinking to the bottom of the cast. In reality, it is nearly impossible to ascertain this through analysis.19

Risks of misidentification/misinterpretation

Surface cavities may originate from a variety of reasons, not just floating debris.

5 Why investigate casting processes? and other FAQs

5.1 Can I tell whether a bronze is cast by the lost wax or

another method, and can I precisely figure out which

variation has been used?

This is a big question. It is possible, but depends on many factors. See all the indications above, and bear in mind

-

the complexity of the process, which may be the result of a combination of several variations (for example indirect and direct; see fig. 68);20

-

that different processes may produce similar features (see all “risks of misidentification/misinterpretation” enumerated above, and Case Study 5).21

5.2 Can I determine more clearly how different casts

relate (or not) to the same model?

Casts of the same model may be any number of things: parts of an edition, replicas, , et cetera (see GI§1.3). But a few clues can point to the relationship between two casts:

-

A reproduction of the topography of a repair on the surface of the object that served as model (but absence of the actual feature), or misinterpretation of a feature from the object that served as a model, would point to a bronze being an after-cast.22

-

Comparing measurements may reveal a discrepancy in size, and if one of the casts is found to be overall consistently smaller, this will suggest that it is an after-cast (see II.4).

-

Traces of the mold-making process such as scratches, remains of the molding material, or more rarely drawings or marks may remain on the original statue, indicating that an after-cast has been taken (figs. 128, 129, see I.6§1.4.2).

While this evidence can point to the fact that other versions are likely to exist, it will not necessarily identify the bronze after which it was cast. However, replication of distinctive marks can point to a specific bronze original, such as lacunae filled during the after-casting process (for example suspension holes in medals).23

5.3 Can I determine what the original model was made of?

This requires both traditional art historical research and close observation. Given the variety of intermediate models between the original and the finished bronze, unless the model is known, it is often impossible to be sure. However:

5.4 Can different artists, founders, or workshops be

distinguished based on specific casting processes?

To make such an assessment, art historical (or archaeological) and technical data must be available in connection with a significant enough group of securely attributed, provenanced (this means known excavation context in the case of archaeological materials), and/or dated comparable bronzes. The specificity of a workshop’s practices will be reflected in a combination of parameters in addition to the casting process (metal and core composition, chasing, patina, et cetera).

In cases where enough data is available, the answers can vary. For instance:

-

Certain idiosyncrasies seen in the interior and exterior surfaces of bronzes (as in subject matter and style) have allowed scholars to identify the work of particular antique foundries.24 The technical evidence from some of Barthélemy Prieur’s (French, 1536–1611) large bronzes tends to indicate that these were produced in the same workshop (see Case Study 5).25

-

Conversely, the greater standardization of processes that is not specific to one particular workshop, such as that found in late sixteenth- to seventeenth-century Venice, may render a precise attribution more difficult.26

Remember as well that for various reasons, artists and/or founders experiment. This seems to have been the case, for instance, with sculptors who were closely involved in the entire process, such as Jean-Antoine Houdon (French, 1741–1828).27 See also Case Study 7.

5.5 What can be learned from understanding the original

casting orientation?

This can help us better understand some of the defects and challenges faced by the founder. Certain orientations may be characteristic of a culture, region, or period. For instance, we have little evidence of horizontal casting so far in the West, but it is still current in South and Southeast Asia (see Case Study 4).28

6 Checklist: How do we investigate the casting technique?

The most important and readily available way of gathering information is close visual examination. This primary and necessary step in the investigation may be assisted by the following (see table 5 Open viewer for a synthesis of available techniques):

-

Good lighting shone at different angles over the surfaces can reveal the topography of tool marks and other features (see II.2§1.2 for guidance).

-

Magnification through portable loupes or binocular microscopy can help characterize details in modeling, defects, and flaws related to the forming of the model and of the mold.

-

Small magnets can help locate iron armatures or core pins that have not been removed but may not be readily visible on the surface (but be warned that some copper alloys may be magnetic; see I.1§3.1 above).

-

A borescope (or endoscope) can afford visual access to internal recesses of hollow casts that are otherwise impossible to reach so as to reveal information about core pins, armature, and the forming of the core that mirrors that of the inner surface of the bronze (see II.2§2.2).

-

Radiography, as seen throughout this chapter, is a source of invaluable information, especially when the interior is not readily accessible (see II.3).

-

3D scanning may be useful for comparison of measurements with other pieces connected to the same model, as it might help to establish the genealogical relationship between them (see II.2§5, II.4§2.2.2).

-

A number of other techniques, including ultrasonic testing and thermography, may be of use to track surface features related to several aspects of the casting process, for instance holes left by armatures and/or core pins (see II.2§3.2 and II.4§2.3.3).

Notes

-

Pingeot, Anne. 2002. “Degas and His Castings.” In Degas Sculptures: Catalogue Raisonné of the Bronzes, edited by Joseph S. Czestochowski and Anne Pingeot, 27–37. Memphis: Torch Press and International Arts.; Lebon, Elisabeth. 2019. “Delhommeau.” In Sculpture of “Les Animaliers” 1900–1950, edited by Edward Horswell, 110–13. London: Sladmore Gallery.. ↩︎

-

These include animal skin captured during indirect casting (see Smith, Pamela H., and Tonny Beentjes. 2010. “Nature and Art, Making and Knowing: Reconstructing Sixteenth-Century Life-Casting Techniques.” Renaissance Quarterly 63:128–79.) or waxed cloth as seen on Donatello’s Judith and Holofernes (see Stone, Richard E. 2001. “A New Interpretation of the Casting of Donatello’s Judith and Holofernes.” In Small Bronzes in the Renaissance, edited by Debra Pincus, 55–67. Studies in the History of Art 62. Washington, DC: National Gallery of Art; New Haven, CT: Yale University Press.). ↩︎

-

Andrew Lacey, personal communication; see also Heginbotham, Arlen. 2014. “Bronzes Dorés: A Technical Approach to Examination and Authentication of French Gilt Bronze.” In French Bronze Sculpture: Materials and Techniques 16th–18th Century, edited by David Bourgarit, Jane Bassett, Francesca G. Bewer, Geneviève Bresc-Bautier, Philippe Malgouyres, and Guilhem Scherf, 150–65. Paris: Archetype.. ↩︎

-

This is notably the case for a number of Barye bronzes (Wasserman, Jeanne L., ed. 1975. Metamorphoses in Nineteenth-Century Sculpture. Cambridge, MA: Fogg Art Museum and Harvard University Press.; Pingeot, Anne. 2002. “Degas and His Castings.” In Degas Sculptures: Catalogue Raisonné of the Bronzes, edited by Joseph S. Czestochowski and Anne Pingeot, 27–37. Memphis: Torch Press and International Arts.; Lebon, Elisabeth. 2019. “Delhommeau.” In Sculpture of “Les Animaliers” 1900–1950, edited by Edward Horswell, 110–13. London: Sladmore Gallery.). ↩︎

-

See also the sculptor Antico’s (Italian, ca. 1455–1528) 1519 reworking of casts for Isabella d’Este, made at the Gonzaga court in Mantua, from the same model and/or molds (Motture, Peta. 2019. The Culture of Bronze: Making and Meaning in Italian Renaissance Sculpture. London: V&A Publishing., 164–67, with earlier refs). ↩︎

-

See for example the sculptor-founder Andrew Lacey’s (British, b. 1969) suggestion in relation to Andrea Riccio’s (Italian, 1470–1532) Shouting Horseman made in ca. 1510–15 (V&A, A.88-1910), cited in Bresc-Bautier, Geneviève, and Guilhem Scherf with James David Draper, eds. 2009. Cast in Bronze: French Sculpture from Renaissance to Revolution. New York: Metropolitan Museum of Art; Los Angeles: J. Paul Getty Museum., 79n50. Also Bewer, Francesca G., Richard. E. Stone, and Shelley G. Sturman. 2007. “Reconstructing the Casting Technique of Lorenzo Ghiberti’s Gates of Paradise.” In The Gates of Paradise: Lorenzo Ghiberti’s Renaissance Masterpiece, edited by Gary M. Radke, 156–82. Atlanta: High Museum of Art; New Haven, CT: Yale University Press. regarding the suggested process that Lorenzo Ghiberti (Italian, 1378–1455) used to create the large relief panels for the Gates of Paradise of the Bapistery in Florence (1425–52). ↩︎

-

See for example Donatello’s (Italian, ca. 1385/86–1466) Judith and Holofernes, bronze with traces of , ca. 1455–60, at the Palazzo Vecchio, Florence. See Stone, Richard E. 2001. “A New Interpretation of the Casting of Donatello’s Judith and Holofernes.” In Small Bronzes in the Renaissance, edited by Debra Pincus, 55–67. Studies in the History of Art 62. Washington, DC: National Gallery of Art; New Haven, CT: Yale University Press.. ↩︎

-

See also Donatello’s Judith and Holofernes (see note 7), where the textile has been added to the wax model (Stone, Richard E. 2001. “A New Interpretation of the Casting of Donatello’s Judith and Holofernes.” In Small Bronzes in the Renaissance, edited by Debra Pincus, 55–67. Studies in the History of Art 62. Washington, DC: National Gallery of Art; New Haven, CT: Yale University Press.). ↩︎

-

Andrew Lacey, personal communication, June 2019, based on his experience with Pamela H. Smith on the Making and Knowing Project, Pamela H. Smith, Naomi Rosenkranz, Tianna Helena Uchacz, Tillmann Taape, Clément Godbarge, Sophie Pitman, Jenny Boulboullé, Joel Klein, Donna Bilak, Marc Smith, and Terry Catapano, eds. 2020. Secrets of Craft and Nature in Renaissance France: A Digital Critical Edition and English Translation of BnF Ms. Fr. 640. New York: Making and Knowing Project. http://edition640.makingandknowing.org.. ↩︎

-

Examples include the numerous animal-shaped inkwells often linked to north Italian Renaissance production. See also Thomas Eakins’s (American, 1844–1916) collection of anatomical casts from dissection experiments now in the Philadelphia Museum of Art. ↩︎

-

See note 9, above. ↩︎

-

Andrew Lacey, personal communication with the authors, May 2019. ↩︎

-

See II.4§1.4 and II.5, although the latter chapter deals only with copper-alloy analysis. For iron analysis, refer to Dillmann, Philippe, and Maxime L’Héritier. 2007. “Slag Inclusion Analyses for Studying Ferrous Alloys Employed in French Medieval Buildings: Supply of Materials and Diffusion of Smelting Processes.” Journal of Archaeological Science 34 (11): 1810–23. as well as II.8§2.2.2 for dating of iron armatures. ↩︎

-

This is probably what happened for the four Virtues on the funerary monument of Henry II and Catherine de Médicis, Basilica of Saint-Denis, Saint-Denis, monument erected in 1567. In three of the Virtues, the main vertical armature has a round profile; on the fourth, the profile is hexagonal (Castelle, Manon. 2016. “Les techniques de la fabrication de la grande statuaire en bronze entre 1540 et 1660 en France.” PhD diss., Université Paris-Saclay / Versailles Saint-Quentin-en-Yvelines.). ↩︎

-

0.5wt% of iron in a copper or copper alloy is enough to stimulate a rare earth magnet, as notably witnessed on the West Mebon Vishnu, made in the Khmer Kingdom during the Angkorian period (CAST:ING. 2018. “Angkorian Founders and Bronze Casting Skills: First Technical Investigation of the West Mebon Viṣṇu.” Bulletin de l’École française d’Extrême-Orient 104 (1): 303–41.). ↩︎

-

These are referred to as leashes in Stone, Richard E. 2006. “Severo Calzetta da Ravenna and the Indirectly Cast Bronze.” Burlington Magazine 148:810–19.. For examples in X-rays of Venetian bronzes, see Motture, Peta, 2003b. “The Production of Firedogs in Renaissance Venice.” In Large Bronzes in the Renaissance, edited by Peta Motture, 277–308. New Haven, CT, and London: Yale University Press., 295, fig. 21; Motture, Peta. 2019. The Culture of Bronze: Making and Meaning in Italian Renaissance Sculpture. London: V&A Publishing., 46. ↩︎

-

For example, the specific chaplets evidenced in Barthélemy Prieur’s (French, 1536–1611) cast discussed in Case Study 5 could only be revealed by endoscopy. For radiographs of chaplets (called spacers in this context) and core extensions in Chinese bronze sculpture see Strahan, Donna. 2010. “Piece Mold Casting: A Chinese Tradition for Fourth- and Fifth-Century Bronze Buddha Images.” Metropolitan Museum Studies in Art, Science, and Technology 1:133–53.. ↩︎

-

Some Indian bronzes were cast face-down to ensure a perfect front; backs are messy and unfinished (see Schorsch, Deborah, Lawrence Becker, and Federico Caro. 2019. “Enlightened Technology: Casting Divinity in the Gupta Age.” Arts of Asia 49 (2): 131–43.). This is still the case, for instance, in sand casting, with the important surface facing down into the drag (David Reid, personal communication, 2019). ↩︎

-

There is little evidence to support this as an invariable phenomenon. For more, see for example Motture, Peta. 2019. The Culture of Bronze: Making and Meaning in Italian Renaissance Sculpture. London: V&A Publishing., 22 and 239n80. ↩︎

-

For example, direct lost-wax elements have even been found incorporated in traditional section-mold casts from the Eastern Zhou Spring and Autumn Period (770–476 BCE) in China, at a transitional moment when lost-wax casting was slowly beginning to be adopted (Strahan, Donna. 2019. “Debating the Use of Lost-Wax Casting in Ancient China.” Forbes Lecture on Scientific Research in the Field of Asian Art. Washington, DC: Freer Gallery of Art and Arthur M. Sackler Gallery, Smithsonian. https://www.freersackler.si.edu/wp-content/uploads/2017/10/Forbes-Lecture-lost-wax-ancient-china.pdf.). ↩︎

-

It can be difficult to distinguish between lost-wax and sand casts. For example, a cast by Antoine-Louis Barye (French, 1796–1875) (see note 9) in the Victoria and Albert Museum, London (S.EX. 65-1882), appears waxy, with a potential wax-to-wax joint underneath. It appears instead to be sand cast, judging from the flashing that points to the use of mold pieces (notes made during a Barye Study Day held at the V&A, November 14–15, 2002; it was also noted that this type of cast was unusual for Barbedienne). The distinction between piece molding and lost-wax casting in ancient China is still a matter of debate among bronze specialists (Notis, Michael R., and DongNing Wang. 2017. “Ancient Chinese Bronze Casting Methods: The Dilemma of Choice.” Materials Research Society. MRS Advances 2 (33/34): 1743–68.). ↩︎

-

For example, in later versions of Barthélemy Prieur’s Gentleman (or Young Man) Holding a Pair of Gloves (probably late nineteenth or early twentieth century), the gloves have been misunderstood and reproduced as an ill-defined block (as seen in the example in the Walters Art Gallery, Baltimore); see Seelig-Teuwen, Regina, David Bourgarit, and Francesca G. Bewer. 2014. “Barthélemy Prieur Fondeur, son atelier, ses méthodes de travail.” In French Bronze Sculpture: Materials and Techniques 16th - 18th Century, edited by David Bourgarit, Jane Bassett, Francesca G. Bewer, Geneviève Bresc-Bautier, Phillippe Malgouyres, and Guilhem Scherf, 18–38. London: Archetype.; Motture, Peta. 2019. The Culture of Bronze: Making and Meaning in Italian Renaissance Sculpture. London: V&A Publishing., 206 and 252n78. ↩︎

-

Numerous examples exist, but see for example a portrait medal of Federico Zuccaro, the original made in 1578 by Pastorino de’ Pastorini (Italian, 1508–1592), in the collection of the Victoria and Albert Museum, London (V&A A.44-1978), which is most likely an enhanced after-cast: http://collections.vam.ac.uk/item/O312298/federico-zuccaro-medal-de-pastorini-pastorino/. ↩︎

-

For instance Mattusch, Carol C. 2009. “Guests, Hosts, and Politics at Herculaneum.” In New Perspectives on Etruria and Early Rome, edited by Sinclair Bell and Helen Nagy, 264–73. Madison: University of Wisconsin Press.. ↩︎

-

See also the work that has been done on Renaissance bronze workshops, for instance Antico (Stone, Richard E. 1981. “Antico and the Development of Bronze Casting in Italy at the End of the Quattrocento.” Metropolitan Museum Journal 16:87–116.; Smith, Dylan, and Shelley G. Sturman. 2011. “The Art and Innovation of Antico’s Bronzes: A Technical Investigation.” In Antico: The Golden Age of Renaissance Bronzes, edited by Eleonora Luciano, 157–85. Washington, DC: National Gallery of Art; London: Paul Holberton.); Giambologna (Flemish, active Florence, 1529–1608) and workshop (Bewer, Francesca G. 1996b. “A Study of the Technology of Renaissance Bronze Statuettes.” PhD diss., University of London.); Severo da Ravenna (Italian, active 1496–before 1538) (Stone, Richard E. 2006. “Severo Calzetta da Ravenna and the Indirectly Cast Bronze.” Burlington Magazine 148:810–19.; Smith, Dylan. 2008b. “I bronzi di Severo da Ravenna: Un approcio tecnologico per la cronologia.” In L’Industria artistica del bronzo del rinascimento a Venezia e nell’Italia settentrionale: Atti del Convegno Internazionale di Studi; Venezia, Fondazione Giorgio Cini, 23 e 24 Ottobre 2007, edited by Matteo Ceriana, 49–80. Verona, Italy: Scripta.; Smith, Dylan. 2013. “Reconstructing the Casting Technique of Severo da Ravenna’s Neptune.” Facture 1:167–81.); Andrea Riccio (Italian, 1470–1532) (Stone, Richard E. 2008. “Riccio: Technology and Connoisseurship.” In Andrea Riccio: Renaissance Master of Bronze, edited by Denise Allen, 81–96. London: Philip Wilson.; Sturman, Shelley G., Simona Cristanetti, Debra Pincus, Karen Serres, and Dylan Smith. 2009. “‘Beautiful in Form and Execution’: The Design and Construction of Andrea Riccio’s Paschal Candlestick.” Burlington Magazine 151 (October): 666–72.); and Adriaen de Vries (Netherlandish, 1556–1626) (Bewer, Francesca G. 2001. “The Sculpture of Adriaen de Vries: A Technical Study.” In Small Bronzes in the Renaissance, edited by Debra Pincus, 158–93. Studies in the History of Art 62. Washington, DC: National Gallery of Art; New Haven, CT: Yale University Press.; Bassett, Jane. 2008. The Craftsman Revealed: Adriaen de Vries, Sculptor in Bronze. Los Angeles: Getty Conservation Institute. https://www.getty.edu/publications/virtuallibrary/9780892369195.html.). ↩︎

-

Motture, Peta, 2003b. “The Production of Firedogs in Renaissance Venice.” In Large Bronzes in the Renaissance, edited by Peta Motture, 277–308. New Haven, CT, and London: Yale University Press.. ↩︎

-

Houdon’s production in the final quarter of the eighteenth century in Paris is discussed in Bassett, Jane, and Guilhem Scherf. 2014. “Jean-Antoine Houdon: Sculptor and Founder.” In French Bronze Sculpture: Materials and Techniques 16th–18th Century, edited by David Bourgarit, Jane Bassett, Francesca G. Bewer, Geneviève Bresc-Bautier, Philippe Malgouyres, and Guilhem Scherf, 107–24. Paris: Archetype.. ↩︎

-

Mechling, Mathilde, Brice Vincent, Pierre Baptiste, and David Bourgarit. 2018. “The Indonesian Bronze-Casting Tradition: Technical Investigations on Thirty-Nine Indonesian Bronze Statues (7th–11th C.) from the Musée national des arts asiatiques – Guimet, Paris.” Bulletin de l’École française d’Extrême-Orient 104:63–139.. Leonardo da Vinci’s (Italian, 1452–1519) proposals for the monumental Sforza horse included a suggestion for casting horizontally; see Bernardoni, Andrea. 2009. “Leonardo and the Equestrian Monument for Francesco Sforza: The Story of an Unrealized Monument Sculpture.” In Leonardo da Vinci and the Art of Sculpture, edited by Gary M. Radke, 94–135. Los Angeles: J. Paul Getty Museum; New Haven, CT, and London: Yale University Press., esp. 119–24, incl. fig. 81. Note that in modern art foundries, an edition may be cast after months or years of experimentation by the founder in search of the ideal sprue system, and the casting orientation may change over this time (Andrew Lacey, personal communication, May 2019). See also Case Study 7§5. ↩︎